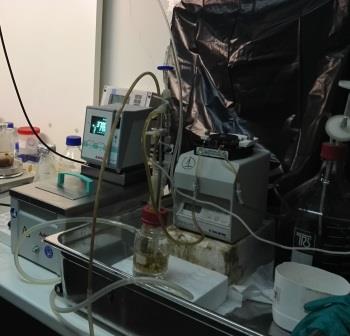

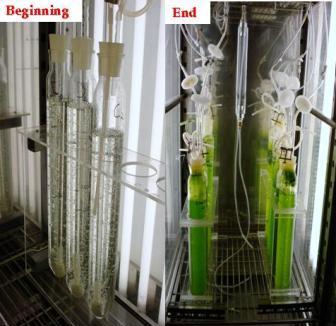

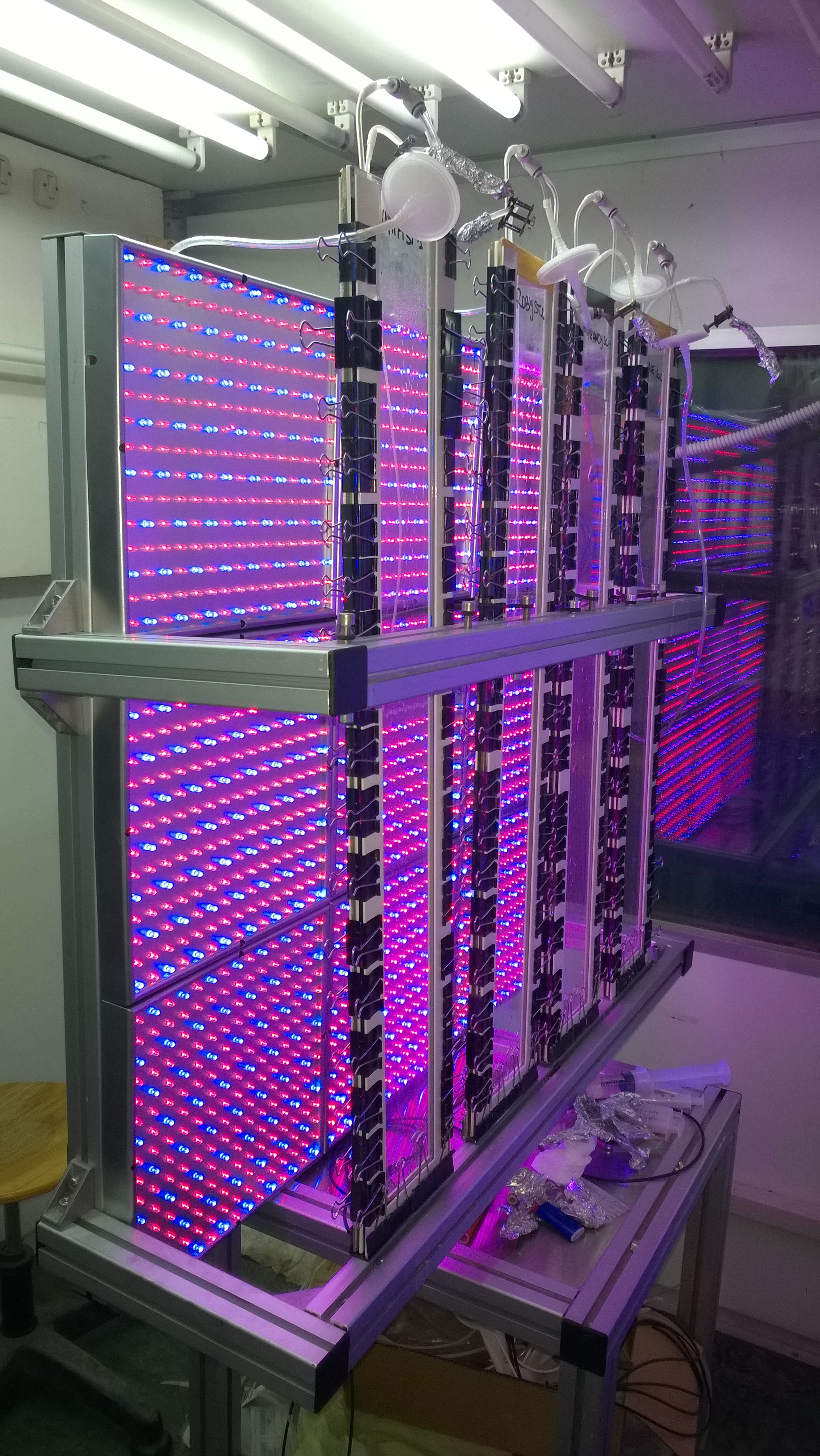

Biofilm fixed bed reactor operated

under continuous conditions

under continuous conditions

Main results

- ABE

production by fermentation of sugar-rich streams (cheese whey, fruit

residues, high sugar content beverages, lignocellulosic hudrolyzed,

....)

- Assessment of the growth kinetics of Clostridium acetobutylicum DSM 79 and of butanol production using reference sugars and complex sugars

- Butanol production process by immobilized Clostridium acetobutylicum continuous Packed Bed Biofilm Reactor (PBBR) systems.

- Integration of the continuous PBBR system with solvent recovery.

- Maximum butanol productivity 13 g/Lh @ 70 (average) g/L of butanol

- Recovery and concentration of butanol (acetone and ethanol) by adsorption

- Techno-economic assessment of the production process from agro-foof wastes

- Life Cycle Assessment

Biofilm fixed bed reactor system operated under

continuous conditions